.jpg)

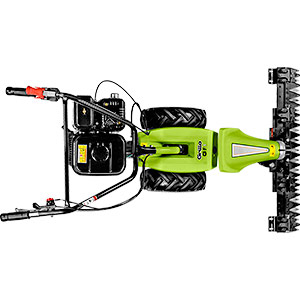

GF 1

Grillo Čeona kosa

|

Grillo GF 1 - 231.900,00

The Grillo GF1 is a perfectly balanced sickle bar; the engine and the P.T.O are positioned in such way to obtain an ideal ground clearance for mowing on slopes.

The centre of gravity was designed to make the GF1 manoeuvrable and safe, even in the most demanding work conditions.

Grillo GF1 has single-speed, the gear is ideal for mowing.

It is available either with a Robin Subaru EX17 OHC or Kohler Lombardini SH265 OHV petrol engines which are of the latest generation and appropriate for mowing in all conditions.

The compact size makes the GF1 a versatile, easily to transport machine which is ideal for mowing small areas.

The two available cutter bars ensure mowing any kind of grass and, apart from that, by means of a practical quick coupling, you can connect the 50 cm rotary cutter and the orientable 80 cm front blade. |

The standard cutter bar is the central model of 86 cm and has a mulch cut mode; the movement is made by using an eccentric flywheel with ball bearings.

It is ideal for the mowing of all type of grass and can be used in rustic areas, fruit orchards or to obtain grass for animal feed.

The cutter bar’s teeth are made of special heat treated steel.

The transmission is equipped with a safety clutch that engages as soon as unseen object should block the blade; so damages to the teeth or blade sections will be avoided.

The blade pressers have a special design and are made of flexible material ensuring constant contact between blade and teeth. |

|

|

The double blade central cutter bar of 96 cm has a Mulchcut mode, both blades move in the opposite direction. This “scissor” like cutting action reduces vibrations at the handlebar considerably whilst mowing and ensures an optimal quality cut.

It's appropriate for mowing all type of grass and can be used in rustic areas, fruit orchards or to obtain grass for animal feed.

The teeth of the cutter bar are made of special heat treated steel.

Apart from that the transmission is equipped with a safety clutch which is engaged if an obstacle blocks the blade, this helps to eliminate damage to the teeth's or part of the blades.

The blade pressers have a special design and are made of flexible material ensuring constant contact between blade and teeth. |

| The GF 1's quick coupling allows you to change implements without ever unscrewing a nut. By withdrawing a pin fixed to the splint you unblock the quick coupling mechanism allowing another implement to be attached. This is a very simple and easy-to-do procedure. |

|

|

The GF1 has a well designed weight distribution to increase its stability whilst moving on slopes. In order to further increase this stability Grillo has a wheel extension kit to increase the track up to 8,5 cm. |

The GF 1's mechanical gearbox with oil bath gears which are housed in a pressed aluminium casing.

The lever on the handlebar's left is fitted with a locking device and engages the blade movement, on the right side, by lowering the red lever you engage the traction.

In order to further increase the operator's safety, the drive lever is equipped with a double control to avoid involuntary actions. The double control can be operated by just one hand. |

|

|

The single-speed gearbox by Grillo GF1 was designed to obtain the ideal speed for mowing.

In order to make a regular mow, the cutter bar can freely incline adapting so to the soil's unevenness.

The handlebar was mounted on anti-vibration rubbers which dampen the vibrations also at the handles; it is adjustable in two height positions.

All controls are easily reached. |

| There are two petrol engine options for the GF1, the Robin Subaru EX17 OHC and the Kohler Lombardini SH265 OHV. Both engines have recoil starter and adopt the latest technical innovations which ensure easy engine starting, reliability, low emissions, reduced consumption, high performance and vibrations reduced to the minimum. |

|

|

Grillo has a lot of accessories to multiply the possibilities of the GF1’s use, such as 50cm the rotary cutter and, for the use during the winter season, the orientable front blade 80 cm. |

The GF1 as with all products by Grillo, has been designed and built to last and retain their value over many years.

All components, from the simplest to the most complex, are of a high quality standard.

Grillo mounts the best engines of the world on its machines!

The GF1 passed very stringent tests to prove the reliability of its transmission, frame structure and of all its components.

Chassis, handlebar, carter, everything is built by Grillo in Italy by using only premium materials and cutting edge technology. All this to achieve a constant and 100% controlled high level quality.

|

|

|

The finish on all Grillo machines consists of a double electrostatic powder coated process. First are the washing baths and preparation, then a first protective coat is applied together with baking in the oven, this turns out to be the best basis for the application of the finish. The second coat consists of powder coating and further baking in the oven at 190°C to produce the characteristic hardness and brilliance.

All the GF1’s s components have been assembled with care in every detail and tested scrupulously by specialised personnel. Final inspection means a machine whose engine has been run in order to check its performance. This is a further and final guarantee of a high quality product. |

| All Grillo products are distributed and serviced by a widespread Grillo specialist dealer net. Spare parts remain available also after a lot of years. |

|